Mechanical characteristics ※ The bed structure is sturdy and can withstand the inertia generated by high-speed motion ※ Three axis 60 meter high-speed displacement can save 50% of non machining time ※ High speed silent screw and silent wire rail reduce thermal displacement with high accuracy ※ High column design, reserved space for the fourth and fifth axes ※ Direct connection high-speed spindle has fast response, greatly improving drilling and tapping efficiency ※ Imported three-axis shield protects screw wire rail and improves machine service life

15989519333 (Mr Xu)

Online consultation Message consultation

Main specifications and technical parameters

| Main technical parameters |

|||

| Mechanical specifications |

name |

Specifications |

Company |

| trip |

X-axis travel |

500 |

mm |

| Travel Y-axis |

400 |

mm |

|

| Z-axis travel |

300 |

mm |

|

| Distance from spindle nose to worktable |

150-450 |

mm |

|

| Distance from spindle center to column slide surface |

425 |

mm |

|

| workbench |

Workbench size |

600×400 |

mm |

| maximum load |

250 |

kg |

|

| T-shaped groove (number of grooves - size - spacing) |

3-14-120 |

mm |

|

| principal axis |

Spindle speed |

20000 |

rpm |

| Main spindle tool holder form |

BT-30 |

||

| Spindle diameter |

Φ100 |

mm |

|

| Feed rate |

Fast moving speed X/Y/Z |

60 / 60 / 48 |

m/min |

| feed rate |

1~8000 |

mm/min |

|

| Machine accuracy |

X/Y/Z-axis positioning accuracy |

±0.005/300 |

mm |

| X/Y/Z axis repetition accuracy |

±0.003 |

mm |

|

| motor |

Spindle motor |

5.5 |

KW |

| X. Y and Z-axis drive motors |

1.5/1.5/ 3 |

KW |

|

| Oil pump |

DY-YBM-750 |

750W |

|

| Tool magazine |

Tool magazine capacity |

16 |

branch |

| Automatic tool change type |

Clamp arm type |

||

| Knife handle specifications |

BT-30 |

||

| Knife handle pull nail |

45 |

degree |

|

| Maximum tool length |

250 |

mm |

|

| Maximum tool weight |

5 |

kg |

|

| Tool change time |

1.5 |

sec |

|

| Land occupation space |

Mechanical height |

2400 |

mm |

| Floor space (length x width) |

1650*2300 |

mm |

|

| Mechanical weight |

3000 |

kg |

|

| Total electrical capacity |

15 |

KVA |

|

| Pressure demand |

0.5 ~ 0.8 |

MPa |

|

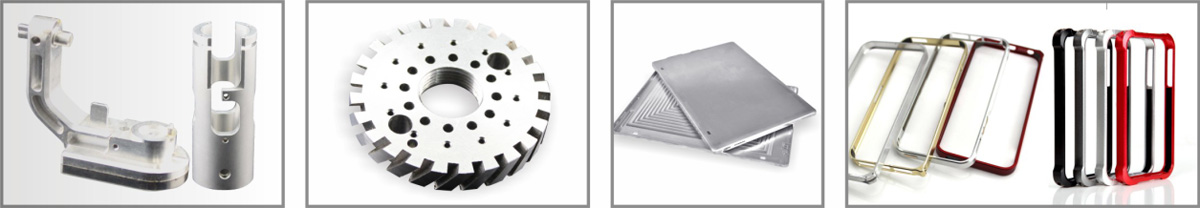

The Best Tool for Mass Production and Processing of Parts

Processing applicationsProcessing application

Precision parts, optoelectronics, mobile phones, 3C products

High rigidity main structureHigh rigidity major structure

All castings are made of MiHanna cast iron high tension casting material, which has strong shock absorption and good wear resistance. It has undergone stress relief and aging treatment to ensure that the machine can maintain the best accuracy for a long time.